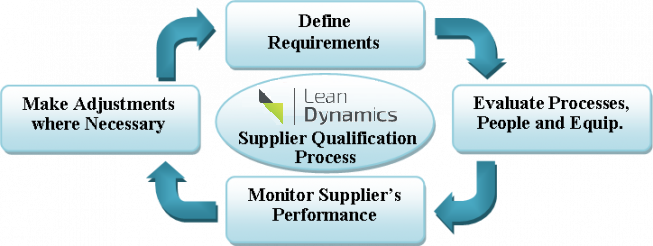

Supplier Qualification

Supplier Base optimization represents a strategic lever for succeeding on the marketplace both in terms of costs management and supporting innovation. The Qualification of new Suppliers such us of new Technologies for Suppliers already qualified is a competing factor that requires consistent criteria; that is crucial for a fair evaluation of the risks and opportunities in the short and medium run. Lean Dynamics Cunsultants, with proven experience in the most competitive sectors, are able to apply the most consolidated qualification standards, including the VDA 6.3, ISO/TS 22163, ISO/TS 15085, DIN 6701, as well as to develop a customized qualification scheme for best fitting specific Client needs.

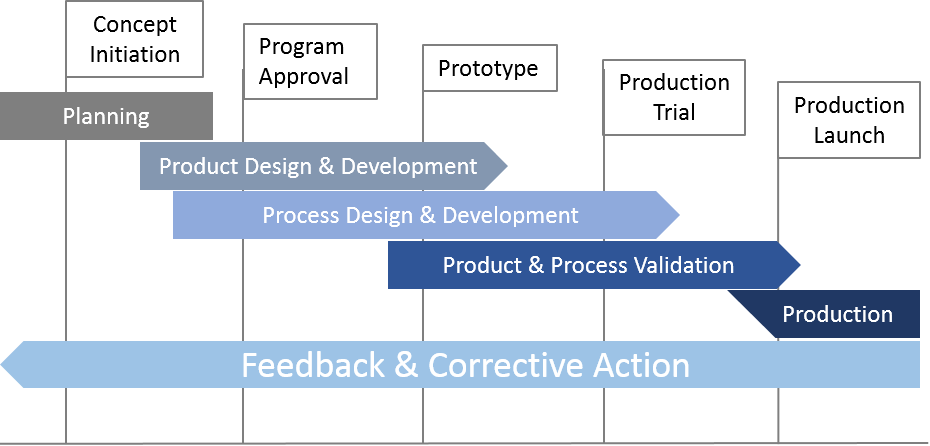

New Product Development - APQP

The development of new products requires the involvement of suppliers from the very early stages of the project following a structured flow of tasks and checks aimed at fully satisfying the customer's requirements. This process, known as Adavnced Product Quality Planning (APQP), requires the involvement of highly qualified and competent personnel that Lean Dynamics is able to provide to Companies that intend to use this effective tool.

Guided Growth

If a supplier has hard times in reaching contractual standards, the use of a third party company such as Lean Dynamics, specialized in the analysis and improvement of production and management processes, represents a valuable tool to allow continuity and quality of the supply avoiding significant losses. Guided growth projects allow to introduce elements of improvement / innovation at process and / or system level avoiding the repetition of critical situations that expose the customer to continuous risks.

Technology Transfer

Technology transfer is increasingly recurring both as a contractual element of international programs, and in response to the challenges that commercial or health crises can cause. Lean Dynamics experts have long experience in various technological processes which they are therefore able to manage even during the transfer phases between sites located at opposite ends of the globe, securing the customer's production continuity.

Crisis Management

When a supplier is going through a critical situation (deliveries and / or quality) such as to put the customer's results at risk (production stoppages, loss of turnover, claims from the field, contractual penalties), the use of a Crisis Manager is the most suitable solution; Lean Dynamics has experience in managing this type of intervention both for companies operating on contract production (i.e. with long takt time) and on large series production (i.e. with short takt time).

Field Management

Lean Dynamics experts have a long experience in the management and execution of defect analysis directly at the end customer. This approach allows gathering a series of technical information right from the context of actual use of the product, easying to identify the true causes of the complained problem quickly and accurately. This approach, developed in the automotive sector, is extremely effective for improving warranty performance in various other sectors, reducing costs and increasing customer / end user satisfaction.

Containment Actions

In the start-up phases of new productions or when the Customer requires the intervention of specialized companies to carry out conformity checks on the outgoing product, qualified personnel capable of carrying out the required checks with accuracy and effectiveness are utilised. Lean Dynamics has a pool of Quality Engineers who can define the Control Plan and organize the workflow quickly and in detail, providing precise and punctual daily reports. Lean Dynamics is able to provide qualified resources for each type of inspection, including certified controls related to special processes including welding, painting, gluing, electrical and mechanical connections.